Coal accounts for more than 60% of the total energy consumption in China's energy structure, and the coal-fired power generation industry is a major source of nitrogen oxides. In recent years, under the adjustment of strategies such as energy conservation and emission reduction, flue gas denitrification technology for coal-fired power plants has gradually matured. Selective catalytic reduction (SCR) technology is currently the most widely used denitrification technology in industry.

SCR (Selective Catalytic Reduction) reducing agent (NH3) reduces NOx in flue gas to nitrogen and water under the action of catalyst. SCR units are generally arranged between the boiler economizer outlet and air preheater inlet, and the catalytic reaction temperature is 300°C to 425°C.

Main advantages.

1, the maximum denitrification efficiency can reach 93%, making the consumption of NH3 optimized.

2. the most widely used, with many successful cases.

Main disadvantages.

1, investment costs and operating costs are the highest among all treatment methods.

2、There is by-product SO3 generation.

3, high design requirements, computer simulation flow field analysis is necessary.

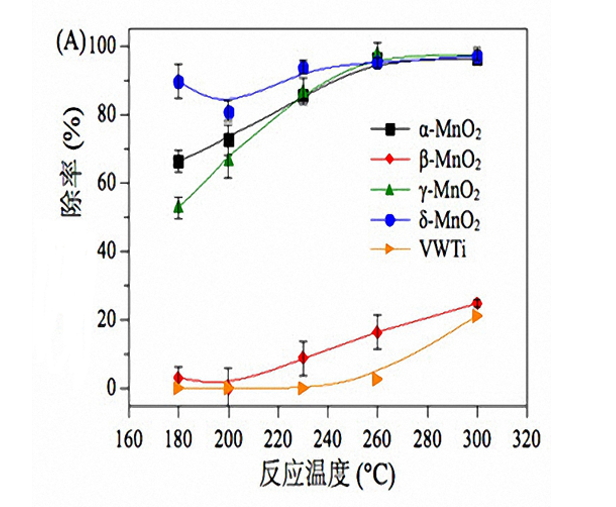

In the whole SCR process system, denitrification catalyst is an important part. At this stage, the most commonly used SCR denitrification catalysts in China are titanium-based vanadium-based catalysts based on V2O5/TiO2. However, due to its high reaction temperature, the common SCR denitrification catalysts can no longer meet the status quo of flue gas treatment in today's non-electric industry where the proportion is gradually increasing. Therefore, research on efficient low-temperature denitrification technology is an important direction for the current denitrification process.

What is low-temperature denitrification catalyst

Catalysts with high denitrification performance in the temperature range of 170℃~300℃ are called low temperature denitrification catalysts.

Difficulties of low-temperature denitrification catalysts Low denitrification activity: denitrification catalyst activity generally decreases as the flue gas temperature decreases, which can result in substandard denitrification efficiency when the temperature is below 200°C and can lead to secondary pollution problems such as excessive ammonia escape.

Poor anti-sulfur poisoning performance: SO2 and SO3 in the flue gas will react with the active sites of the catalyst, resulting in a reduction in the number of active sites and a decrease in denitrification performance, so the existing low temperature denitrification catalysts, which need to be used under low sulfur flue gas conditions, are difficult to apply to high sulfur flue gas.

Serious clogging poisoning: SO3 formed by oxidation of SO2 in flue gas will react with NH3 to produce sulfur ammonium salts, which will attach to the catalyst surface and cause the catalyst active sites to be covered, and the sulfur ammonium salts will further adsorb fly ash in flue gas, which will aggravate the clogging and lead to rapid catalyst deactivation.

Medium and low temperature denitrification catalyst

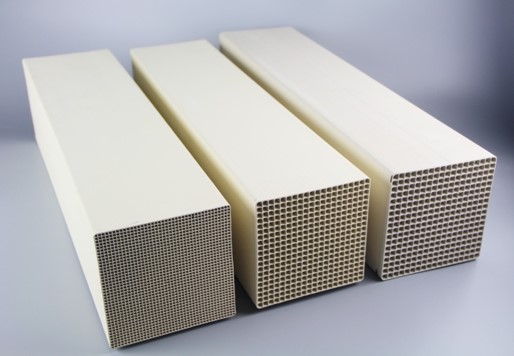

Yuanchen technology, medium and low temperature denitrification catalyst, using masking agent to cover the high temperature catalytic active site, low temperature catalyst in the polymetallic effect to promote low temperature conversion, still has high activity at 170 ~ 380 ℃, can be highly efficient in the removal of NOx, dioxins in flue gas. The product has been successfully applied to steel sintering, coking, waste incineration and other flue gas conditions, and has been awarded as a provincial high-tech product. The common number of holes is 25, 30 and 35.

Anhui Yuanchen Environmental Protection S&T Co., Ltd.(hereinafter referred to as "Yuanchen Technology"), which was established in 2005, has developed into a modern comprehensive enterprise integrating dust bag, denitrification catalyst and third-party testing after 16 years of rapid development. In the next step, with the vision of "becoming the guardian of global ecological environment", Yuanchen Technology will deeply plough into the environmental protection industry, take advantage of the national ecological civilization construction pattern, continuously optimize the management mode, innovate and upgrade from itself, and build a new future of co-business, co-build, share and win!

Source: Anhui Yuanchen Environmental Protection Technology Co., Ltd.

Tel:17333203296